Nothing short of perfection

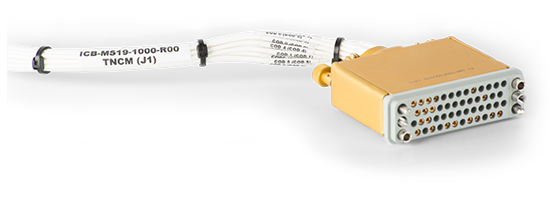

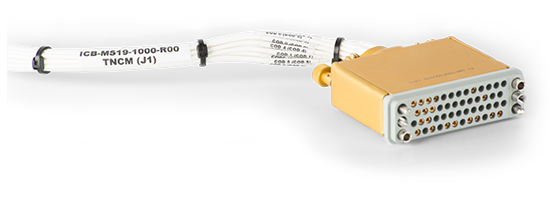

At our North American manufacturing facility, Quester Tangent designs and builds cable assemblies using many conductor configurations, including: single conductors; multi-conductor cables, such as CAT 5e, RF cables; and Ethernet cables. The key to accurate, consistent, high-quality cables is automation. We use state-of-the-art robotics to cut, strip, label, and crimp our conductors.

We work with wire gauges from 30 to 6 AWG and with many types of insulation, including Teflon, PVC, and irradiated cross-linked Polyolefin.

Our array of connector types includes D-Sub series, MIL-DTL-5015 circular, DIN 41612 rectangular, MIL-C-28748, RF (SMA, N, TNC, BNC, U.FL, MMCX, SSMB), and M12, all from quality manufacturers, such as ITT VEAM, Amphenol, Harting, Positronic, and AMP.

Benefits

Versatile. Assemblies are precisely tailored to fit specific client needs.

Reliable. Quality is assured through rigorous testing during the assembly process.

Durable. Custom Tedlar labeling is ideal for harsh operating environments.

Services

Cutting & Stripping. Our automated cutting and stripping machine cuts wires to length and strips the ends according to the termination requirements for the connectors being used. The automated process ensures accurate, repeatable results without nicking or cutting the conductor strands.

Crimping. Our automated crimping machine exactly positions the contact in relation to the prepared conductor end and applies the precise amount of pressure to crimp the contact securely and consistently without damaging the conductor.

Crimping. Our automated crimping machine exactly positions the contact in relation to the prepared conductor end and applies the precise amount of pressure to crimp the contact securely and consistently without damaging the conductor.

Assembly. Our cable bundles are assembled using low-profile, rounded cable ties without sharp edges for increased safety and ease of use when they are pulled through conduits. Assemblies can also include cable sheathing applied over completed bundles for neatness and protection.

Labeling. Our automated labeling machines produce industry-leading labels printed on Tedlar for demanding applications. We can apply a highly readable, durable identification label to individual conductors and completed wire bundles. We can print images and double-sided labels to allow 180º viewing.

Testing. We test complete cable assemblies using an automatic test station that uses custom programming to perform 100% continuity and short-circuit testing specific to each assembly design. Available testing includes a four-wire resistance check, in-line component tests (for capacitors, resistors, and diodes), and HIPOT test.